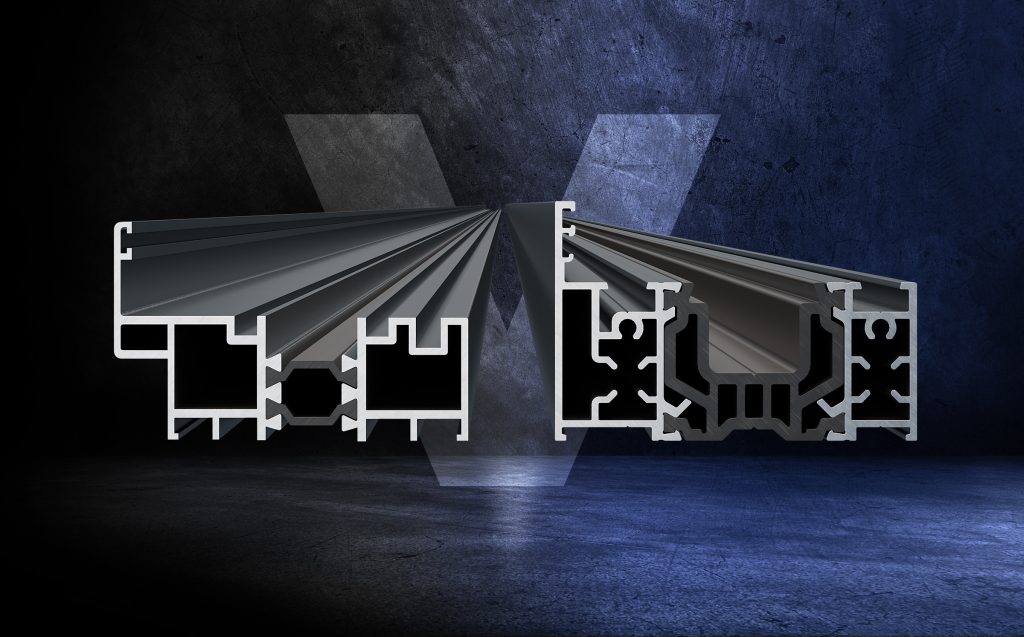

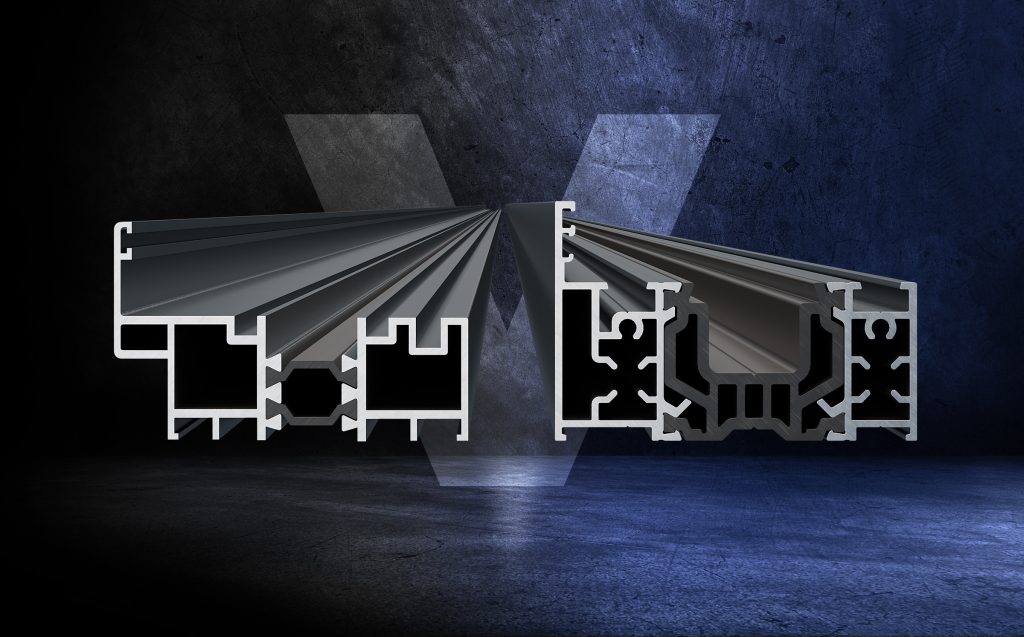

Thermlock® v polyamide, the difference is clear

When the foundations for the Sheerline system were laid, one of the weaknesses of existing aluminium systems that needed addressing was the sectors reliance on polyamide thermal breaks.

While polyamide did create a ‘thermal barrier’ that met older thermal efficiency standards, the material struggled to meet the improved standards required by the UK’s carbon reduction commitments. This need to improve the energy efficiency of the nation’s homes has never been clearer than it is right now, with the average household energy bill set to rise to a staggering £3,549 this year, with further increases forecast in 2023.

From the start is was clear that a better solution was required, a thermal break designed for more stringent legislation, that also overcame some of the other inherent limitations of polyamide. It was this need that led to Thermlock®, one of the eureka moments for Roger Hartshorn and his R&D team, when they created the Sheerline system in 2018/2019.

Thermlock® multi-chambered thermal breaks are unique to Sheerline and sit at the heart of every Sheerline product. Made from a special high melting point formulation, which is almost half as thermally conductive as polyamide, Thermlock® allows for wider, integrated one-piece designs that add rigidity to profiles, eliminating the distortion that can occur with separate top and bottom polyamide thermal breaks. This means that every Sheerline product meets the new Part L standards with regular double glazing – helping customers supply high performance products without adding cost. With Sheerline, Part L compliance comes as standard.

While other systems companies are busy trying to shoehorn solutions into their legacy systems, either adding cost via foam inserts or forcing customers to ‘upgrade’ to expensive triple glazing, or much wider systems to meet these new standards, Sheerline customers are left with a competitive advantage and a clear easy to understand, and perfectly matched product offer.

Drawing on their years of experience within the fenestration industry the Sheerline team also knew

Thermlock® needed to be as fabricator and installer friendly as possible and its improved screw retention over polyamide helped Sheerline systems pass the most rigorous of tests with ease.

Having already invested over £1million in tooling for its own in-house produced Thermlock® thermal breaks, Sheerline and its customers are already benefiting from the clear advantages this technology brings with better performance and integrated on-site manufacture minimising the risk of third party supply issues. Coupled to the ability to react quickly to any future tightening of thermal requirements, Sheerline customers can be confident they’ll be ready once again to succeed in an ever-changing marketplace.